FUNDAMENTALS OF TEXTILES

INTRODUCTION

Food, shelter and clothing are the basic needs of mankind. Clothing is made from textiles and our homes are made more comfortable and attractive by the use of textiles.

Textiles have such an important bearing on our daily lives that everyone should know something about them. From the earliest times, people have used textiles of various types for covering or modesty, warmth, personal adornment, to display personal wealth and even for biomedical and technical purpose.

A study of textiles will show, for example why certain fabrics are more durable and serviceable for specific purposes. Complete knowledge of textiles will facilitate an intelligent appraisal of standards and different qualities of textile products.

KEY WORDS:

Textiles: The word textile comes from the Latin term “Textere” meaning to “Woven”. Today the word textile is more generalized and refers to the product made from fibres.

Fiber: A fiber is defined as any product capable of being woven or otherwise made into a fabric. It may be thought of as the smallest visible unit of textile production or a fiber can be defined as a pliable hair like strand that is very small in diameter in relation to its length. Fibres are the fundamental units or the building blocks used in the making of textile yarns and fabrics.

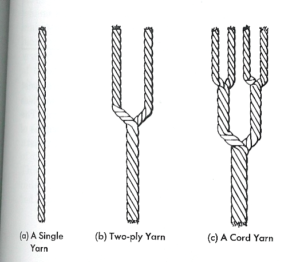

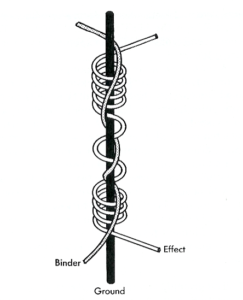

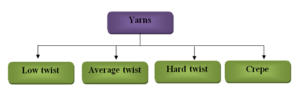

Yarns: Yarns are produced by twisting or spinning of the textile fibers

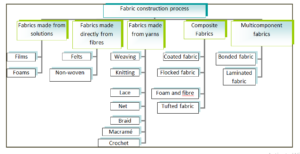

Fabric: Fabric is a planner structure produced by interlacing or interlooping of yarns.

REASONS FOR STUDYING TEXTILES

- A study of Textiles will show, for example why certain fabrics are more durable and therefore more serviceable for specific purpose.

- It will explain why certain fabrics make cool wearing apparel.

- Complete knowledge of textiles will facilitate an intelligent appraisal of standards and brands of merchandise and will develop the ability to distinguish quality in fabrics.

- The customers get idea about how to buy and what to buy.

TERMINOLOGY USED IN TEXTILES

- Filament: Long continuous fiber strands of indefinite length measured in yards or meters.

- Staple: These fibers measured in inches or centimeters and range in length from ¾ of an inch to 18 inches.

- Abrasion resistance: It is the ability of a fiber to withstand the rubbing or abrasion it gets in everyday use. I t contributes to fabric durability.

- Absorbency or Moisture Regain: Is the amount of water a bone dry fiber will absorb from the air under standard conditions of temperature (70 Degree F) and moisture(65% relative humidity).

- Flexibility: Is the ability of a fiber to blend easily.

- Chemical reactivity: Is the effect of acids, alkali, oxidizing agents, solvents.

- Cohesiveness: Is the ability of fibers to cling together during spinning. Not important in continuous filament.

- Cover: The ability to occupy space for concealment or protection.

- Creep: It is delayed elasticity. Recovers gradually from strain.

- Dyeability: It is the fibers receptivity to coloration by dyes.

- Elastic recovery: Is the ability of fibers to recover from strain.

- Elasticity: Is the ability of a stretched material to return immediately to its original size.

- Electrical conductivity: Is the ability to transfer electrical charges.

- Elongation: Is the ability to be stretched, extended, or lengthened. It varies at different temperatures and when wet or dry.

- Feltability: It refers to the ability of fibers to mat together.

- Flammability: Is the ability to ignite and burn.

- Hydrophilic: Fibers are able to absorb water easily or water loving.

- Hydrophobic: Fibers that have difficulty in absorbing water and are only able to absorb small amounts are called hydrophobic. Example: All man made fibers expect rayon.

- Hand: It is the way a fiber feels: silky, harsh, soft, crisp, dry.

- Heat conductivity: Is the ability to conduct heat away from the body

- Hygroscopic: Those fibers, which absorb the moisture from air.

- Heat sensitivity: Is the ability to soften, melt, or shrink when subjected to heat.

- Luster: Is the light reflected from a surface. More subdued than shine; light rays are broken up.

- Loft or compression resiliency: Is the ability to spring back to original thickness after being compressed.

- Pilling: Is the balling up of fiber ends on the surface of fabrics.

- Static Build Up: Problems such as sparks and clinging clothing occur with the build – up change on the fiber surface.

- Thermoplastic fiber: Those fibers, melts or soften when heat is applied.

- Specific gravity and density: These are measures of the weight in grams per cubic centimeter, and specific gravity is the ratio of the mass of the fiber to an equal volume of water at 4 degree centigrade.

- Stiffness or rigidity: Is the opposite of flexibility. It is the resistance to bending or creasing.

- Solubility: It is the test used to identify the textile fiber by dissolving them in the respective solutions.

- Tensile Strength: Is defined as the ability to resist stress and is expressed as tensile strength (pounds per square inch) or as tenacity (grams per denier).

- Wicking: Is the ability of a fiber to transfer moisture along its surface.

- Sunlight resistance: Is ability to withstand degradation from direct sunlight.

- Ageing Resistance: Resistance from deterioration of textiles resulting from exposure to destructive elements encountered in normal everyday use such as sunlight, heat, moisture or oxygen.

- Moth Resistance: Resistance from moths, which is generally attracted by wool, as it is a living natural fiber or protein fibers.

- Mildew Resistance: Resistance from the Mildew, mold, fungus, and rot all which are formed on the fabrics by exposure to warm, moist atmosphere or soaps and sizing used in processing, which become food for vegetable organisms.

- Resistance from Microorganisms: Resistance of textile fibers from any of the microorganisms for the hygienic purpose.

REFERENCES

- Corbman B. P (1983) Textiles-fiber to fabric, Mc Graw-Hill lnt., USA

- Kadolph S J (2013) Textiles: Pearson New International Edition, Pearson Education Ltd, Asia

- Noemia, D Souza (1998) Fabric Care , New Age Publications

- Vatsala, R. 2003. Textbook of Textiles and Clothing. New Delhi. Indian Council of Agriculture Research

- http://bieap.gov.in/Pdf/CGTPaperII.pdf

- https://www.textil.eu/en/articles-18/

- https://www.ballyribbon.com/glossary/

- https://en.wikipedia.org/wiki/Glossary_of_textile_manufacturing

ASSIGNMENT

- List the various products made of textiles in our day to day life.

- What are the uses of textiles in our life? List them.

- What are the textile products we use other than dress/clothes.

CLASSIFICATION OF TEXTILE FIBRES

- INTRODUCTION

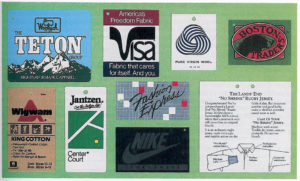

The textile industry uses many fibers as its raw materials. As a result of the development of new fibers, difficulties arise in textile industry in terms of identification, classification. Hence, classification of textile fibers was compounded by the trained manufactures to identify each of the fibers with the different trademarks.

Textile fibers are classified according to the source and the length of the fibers.

- CLASSIFICATION OF FIBERS

Textile fibers are classified in the following ways

- According to the Source

- Length of the fiber

2.1 ACCORDING TO THE SOURCE:

According to the source from which textile fibers are obtained, fibers are broadly classified in two ways viz,

- Natural

- Manmade

- Synthetic

2.1.1. NATURAL FIBERS:

Natural fibers are further divided into following three categories. They are,

- Vegetable fibers or cellulosic fibers

- Animal fibers or Protein fibers

- Mineral fibers

a. Vegetable fibers ‘or’ Cellulosic fibers:

As the name indicates these fibers are obtained from vegetable source i.e. plants and cellulosic matter is the base for all these fibres.

This category includes the most important textile fiber – Cotton, which makes up nearly 50% of total fibers used in world (by weight). Hence it is considered as major fiber. This category also includes other minor fibers such as Linen, Jute, Pineapple, etc.

b. Animal Fibers ‘or’ Protein fibers:

There are several animal fibers each obtained from a different source, but only two are recognized as major textile fibers – Wool and Silk. They make up small proportion in the market (by weight) but a much higher proportion by value. Other minor fibers in this category are Mohair, Cashmere, Angora, and Camel hair.

c. Mineral Fibers:

Asbestos is a natural fiber obtained from varieties of rock. It is a fibrous form of silicate of magnesium and calcium containing iron, aluminum and other minerals. It is an acid proof, rustproof, flameproof fibre. However, the use of asbestos is now rapidly declining following the discovery of health risks from asbestos dust.

2.1.2. MANMADE FIBERS:

These refer to those fibers that are not naturally present in nature, but are synthesized.

a. Cellulosic Source:

These are the fibers manufactured from a natural polymer Cellulose that is obtained from wood. These are further divided into:

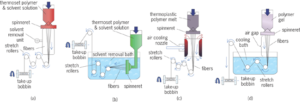

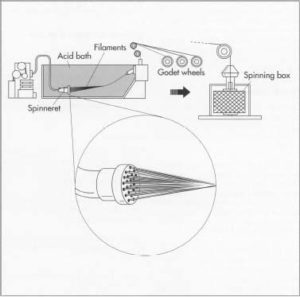

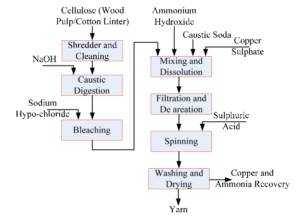

i. Regenerated fibers: The starting product is cellulose, which is dissolved in sodium hydroxide and the viscous solution is extruded through spinneret into dilute H2SO4.

ii. Modified Regenerated: The raw material here is also cellulose, but these fibers are modified chemically so that polymer can be dissolved in an organic solvent and extruded into hot air which evaporates the solvent.

b. Protein Fibers:

These are made from the protein source but are not being manufactured at present. They include Soya bean and Azlon.

c. Mineral Fibers:

These fibers are glass, steel and carbon, all of which are found in industrial end uses viz., Glass is used for low cost reinforcement plastic for ships, cars and thermal and electrical insulation etc.,

Steel is reinforced rubber in tyres and belts for filters where chemical resistance is important.

Carbon fibers are used where high performance is required i.e. aircraft’s parts, tennis and squash rackets etc.

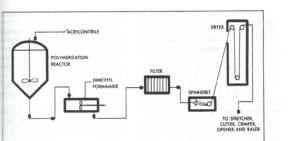

2.1.3. SYNTHETIC FIBERS:

The term synthetic means that the polymer is entirely man made from chemicals. These group fiber properties are dependent upon their chemical compositions and kinds of molecular orientation. The group includes three major fibers and several minor ones. The major ones include Nylon (polyamide produced in U.S.A in 1938), Polyester (produced in 1953), Acrylic (produced in 1948).

2.2.CLASSIFICATION OF FIBERS BY LENGTH:

According to length, fibers are classified into two types:

- Staple fibers

- Filament fibers

2.2.1. STAPLE FIBERS:

Natural fibers are short length fibers which measure in inches or fraction of inch Ex: ¾ to 18 inches. Expect silk, all other natural fibers are staple fibers. Manmade fibers are made in filament form but can be cut into short staple lengths for particular end uses.

2.2.2. FILAMENT FIBERS:

Long fibers those measured in yards or meters are known as filaments. Silk and all man-made and synthetic fibers are filaments.

REFERENCES

- Corbman B. P (1983) Textiles-fiber to fabric, Mc Graw-Hill lnt., USA

- Kadolph S J (2013) Textiles: Pearson New International Edition, Pearson Education Ltd, Asia

- Vatsala, R. 2003. Textbook of Textiles and Clothing. New Delhi. Indian Council of Agriculture Research

- http://gpktt.weebly.com/classification-of-textile-fibers.html

- https://clothingindustry.blogspot.com/2017/12/classification-textile-fibers.html

- https://www.youtube.com/watch?v=76xEqJXhqrk

- http://bieap.gov.in/Pdf/CGTPaperII.pdf

ASSIGNMENT

- Collect textile fibers from their products

- Identify textile fibers by their length

- Collect natural fibers in their original form

PROPERTIES OF TEXTILE FIBRES – Primary

- INTRODUCTION:

The second step in the process of learning textiles is to know how to qualify a material for a specific use. In order to do so the product must possess some essential characteristics or properties. It is generally agreed that the essential qualities or primary properties of a fibre like length, strength, flexibility or pliability, cohesiveness or spinnability and uniformity are adequate. Other properties may be desirable in all fibres but they are not essential. So they can be termed as secondary properties. These may improve the quality of textile fibres and thus get the consumers’ satisfaction.

- PROPERTIES OF TEXTILE FIBRES:

The properties of the fibers can be divided into:

- Primary properties

- Secondary properties

- Thermal properties

- Chemical properties

- Biological and other properties

2.1 PRIMARY PROPERTIES

Primary properties of the fibers include:

- Length

- Strength or Tenacities

- Flexibility or Pliability

- Cohesiveness or Spinnability

- Uniformity

2.1.1 Length:

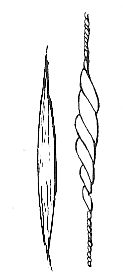

Textile fibres are available in different lengths. Filaments are long continuous fibres of indefinite length measured in yards or meters. Staple fibres are short fibres measured in inches or centimeters and range in length from ¾ ” to 18″. All natural fibres except silk are staple fibres. Man-made and synthetic fibres are all filament fibres. Sometimes filament fibres are cut into staple length. Several thousands of filaments are taken in the form of a loose rope or strand, often made crimpy and are cut to produce staple fibres ranging in length from 1″ to 5″. The rope of fibres is also refered to as ‘Fibre tow’.

Fibrous materials must possess greater length than the diameter. This is referred as length to width ratio. A minimum ratio of 100:1 is considered essential. Majority of the fibres have greater length than the diameter.

2.1.2 Strength or tenacity:

Strength is the second primary property of all textile fibres. In order to be serviceable, all fibres must possess this quality. The strength must be adequate for processing or spinning into a yarn and further making into a fabric. Fibres may vary in strength and the strength within a fibre may not be uniform throughout. It depends upon mainly the molecular structure of fibres.

The strength of a fibre is defined as the ability to resist stress and is expressed in grams per denier (finesses of fiber). It may vary from fibre to fibre. Strength can also be measured in pounds / sq.inch. This is referred as ‘tensile strength’. The strength of a fibre can never be confused with strength of yarn or fabric since it is possible to produce very strong and durable materials from weak fibres.

A strong fibre is durable, has a better tear strength and resists sagging and pilling. The tenacities of some selected fibres of consumers’ interest are given below.

Fibre Tenacities

Under Standard Conditions (70 Degree Fahrenheit & 65% RH)

- Cotton – 0

- Silk – 5

- Wool – 5

- Rayon – 5 to 2.4

- Acetate – 2 to 1.5

- Nylon – 5 to 5.9 (High tenacity fibres– 5.9 to 9.2)

- Polyester – 4 to 7.8

- Glass – 0

Glass ranks first in tenacity than the other fibres. Next is Nylon and Polyester. Some of these fibres loose or gain strength when wet. A good example for loss of strength during wet condition is Rayon and for gaining strength is cotton.

2.1.3 Flexibility or Pliability:

Certain degree of flexibility or pliability is necessary for a fibre to be used as a textile fibre. A textile fibre needs to be bendable. For example a glass rod cannot be bent without breaking, but a glass filament can be bent easily. This property is essential to create yarns and fabrics that can be creased, have the quality of drapability, ability to move with the body and should allow for the free movement and also be comfortable. A stiff fibre will make stiff fabrics, which cannot be used comfortably.

2.1.4 Cohesiveness or Spinnability:

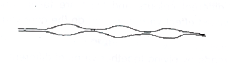

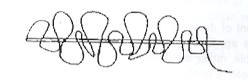

Cohesiveness is the ability of the fibres to stick together during spinning. The cohesiveness in fibres may be due to the longitudinal contour or the cross sectional shape that enable them to adhere together. The surface or the skin structure of the fibre may also influence cohesiveness. For example, wool fibre possesses scales on the outer skin of the fibre which help in interlocking fibres while spinning. If the surface or shape of a fibre does not contribute for cohesiveness, the same can be compensated by using filament yarns. As filaments are present throughout the length of the yarns, there is little necessity of having the ability to stick. So this cohesiveness is often conveniently replaced by spinning quality. Polyester is having the lowest cohesiveness but it can be made into staple yarns by using less percentage of cotton and later burning it through carbonising process.

2.1.5 Uniformity:

In order to produce fine yarns, uniformity in the raw material is required. Fibres that are used to produce yarns need to be similar in length and width, in spinning quality and in flexibility. All man-made and synthetic fibres are uniform since they are made through artificial processing. But in case of natural fibres, it is not so. Fibres differ is many aspects, and so it is not possible to produce very fine materials in natural fibres unless some extra processing is done. The yarns composed of uniform fibres are smooth and even.

REFERENCES

- Corbman B. P (1983) Textiles-fiber to fabric, Mc Graw-Hill lnt., USA

- Kadolph S J (2013) Textiles: Pearson New International Edition, Pearson Education Ltd, Asia

- Noemia, D Souza (1998) Fabric Care , New Age Publications

- Vatsala, R. 2003. Textbook of Textiles and Clothing. New Delhi. Indian Council of Agriculture Research

- Wynne A (1997) Textiles The Motivate Series, Macmillan

- http://bieap.gov.in/Pdf/CGTPaperII.pdf

- http://textilelearner.blogspot.com/2012/02/properties-of-fiber-properties-of.html

ASSIGNMENT

- Identify the important properties of the textile products

- List any five important primary properties we need for clothes and why?

- Identify strongest fiber

PROPERTIES OF TEXTILE FIBRES – SECONDARY

- INTRODUCTION:

Secondary properties include: Physical shape, lustre, density or specific gravity, absorbency, electrical conductivity, elasticity, elastic recovery, pilling, hand, feltability. The following is the detailed information about the characteristics of textiles fibres.

- SECONDARY PROPERTIES:

- Physical Shape

- Density

- Lustre

- Absorbency

- Elasticity

- Abrasion Resistance

- Hand

- Pilling

- Loft and Resiliency

- Static Electricity

- Feltability

2.1 Physical Shape:

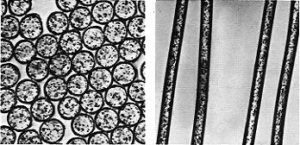

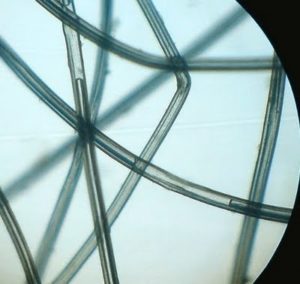

The physical shape of the fibre is an important factor in determining many of its properties. It includes the surface contour (smooth, rough, serrated), the shape of the cross section and the width and length of the fibre. The shape of the cross section influences certain factors such as lustre, body and hand. The surface contour in turn influences cohesiveness, resiliency, loft and thickness. It contributes to resistance to abrasion, pilling and comfort factors such as absorbency and warmth. The cross sectional shape can be changed for all artificial fibres unlike natural fibres as the fibres are molded though spinnerets.

2.2 Density:

Density is the mass of a unit volume of material. It is expressed as gms/cubic cm or pounds per cubic foot. The specific gravity of a fibre indicates the density relative to that of water at 4oC. All textile fibres are heavier than water except olefin fibres. Only these fibres float on water. Cotton, wool fibres are heavy and nylon is comparatively lighter. The lower the density of fiber the more the covering power they possess. A pound of wool and a pound of nylon weigh the same but the fibres are more in nylon than in wool. High density results in heavy fabrics, low density results in light weight fabrics.

A light weight fibre helps a fabric to be warm without being heavy. Acrylic fibres being light comparatively are wool like in appearance and are used extensively instead of wool to produce light weight sweaters and blankets.

2.3 Lustre:

Lustre is the amount of light reflected from a surface. It is more subdued than shine. Light rays are broken up into many short rays unlike the shine in which the light ray is reflected back wholly without any breaks. The lustre is due to smoothness, fibre length, flat or lobal shape. It determines the fibres natural brightness or dullness. The natural fibre silk has the high lustre and cotton is the dullest natural fibre. All man-made fibres are produced with controlled lustre. It is not always desirable to produce bright fabrics. So the lustre is controlled by the addition of pigments such as titanium dioxide in spinning solution. The lustre in natural and man-made fibres can also be improved by various finishing techniques. For example the lustre in cotton is improved by mercerization.

2.4 Absorbency:

Generally textile fibres have certain amount of water as an integral part of the fibre. All most all textiles fibres are naturally hygroscopic (i.e they pick up moisture from air). But the amount of moisture the fibres absorb may differ. Absorbency is the ability to take in moisture and moisture regain is the percentage of moisture a bone-dry fibre will absorb from the air under the standard conditions of temperature and moisture. Fibres that absorb water easily are known as hydrophilic (water loving) fibres. Natural protein and vegetable fibres, rayon and acetate are hydrophilic fibres. Fibres that have difficulty in absorbing water are known as hydrophobic fibres.

Many synthetic fibres are hydrophobic in nature. The absorbency of glass fibre is ‘0’. Absorbency is an important factor in all textile fibres especially those which are used for apparels as it influences many other fabric properties such as comfort, warmth, water repellency, static build up, dyeability, shrinkage, wrinkle resistance etc. It is easy to wash a hydrophobic fabric as it does not absorb stains and it dries quickly.

Among the textile fibres the natural protein fibres silk and wool are the most absorbent of all fibres. Next comes the natural and man-made cellulosic fibres.

The absorbency of a textile fabric is controlled by the type of yarn and fabric construction and also by finishing. For example: in cotton, the absorbency is increased by kier boiling, mercerization and napping. Pile construction increases the area of absorption.

2.5 Elasticity:

Elasticity is defined as the ability of fibres to return back to original shape after being stretched. Elastic recovery is the ability of fibres to return from strain and is expressed in percentage. If a fibre returns to original length after stretching to a specified length, it is said to have 100% elastic recovery.

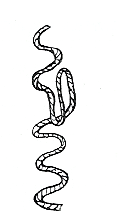

Elasticity is required in fabrics when subjected to stretch during wear. This property is influenced by the side chains and cross linkages between the molecules. If strong bonds are present in between chains of molecules, the fibre tends to return to its original length. If the bonds are not strong it can’t recover to its original length but takes up the new shape. Thus creases appear on the material. Some fibres show immediate elastic recovery, and some fibres may show delayed elastic recovery. For example, the creases on a silk material disappear if hung overnight. Wool, silk, viscose and nylon are having good elasticity. Cotton and acetates have poor elastic recovery. Polyester has moderate elongation but has good elastic recovery. It is apparent that both the elongation and elastic recovery are considered together in evaluating fibres, yarns and fabrics.

2.6 Abrasion Resistance:

It is the ability of fibres to withstand the rubbing or abrasion it gets in everyday use. All fabrics irrespective of the end use are subjected to rubbing of some kind during wear. The fabric has to withstand rubbing, otherwise the fabric will show signs of damage and become unsightly. The resistance may be due to the tough outer layer and flexible molecular chains of the fibre. The size of the yarn also influences the abrasion resistance. Thick yarns resist abrasion than thin yarns. Yarn uniformity is also important as irregular yarns are abraded more easily than uniform yarns. Smooth fabrics with compact yarn arrangement are less susceptible to damage by abrasion than those with irregular surface in the low count.

Nylon has excellent resistance and acetate and glass have very poor abrasion resistance when compared to silk & wool. Cotton has better abrasion resistance. This is an important property, as it influences the durability and increases the resistance to splitting.

2.7 Hand:

Hand is the way a fibre feels. It can be only detected by feeling it in between fingers. The hand varies due to the cross sectional shape, the length and diameter, the flexibility, the compressablity, resilience, surface contour of the fibres, surface friction and thermal characteristics of fibres .

The hand and drape of a fabric are inter dependent. The hand of a fabric may vary from very pliable to very stiff, from very soft to very hard, from very limpy to very springy, from rigid to high degree of stress, form very smooth to very rough, from slippery to harsh, from very cool to very hot and from wet to dry.

The hand of a yarn and fabric should not be confused with the hand of a fibre. It is possible to produce smooth yarns from rough fibres and vice versa.

2.8 Pilling:

Ball like structures are often observed on polyester and nylon materials after few washes which make the material unsightly. Pilling is nothing but the balling up of fibre ends on the surface of fabrics. It is one of the disadvantages of staple fibre fabrics. In natural fibres the balls cut away from the fabric easily but synthetic fibres are so strong that they do not break away rapidly from the fabric. So the strength of fibres is a basic factor in the problem of pilling. Pills usually occur in areas that are abraded or subjected to abrasion during wear. Usually at the armpits of garments and back and lower edge of sarees, pilling can be seen. It can be made better by removing pills. But it is almost impossible to remove pilling from synthetics unless it is given singeing finish. In this the fabric passes through gas flames, so that the balls are burnt off. In order to inhibit the formation of pills on materials, they are given special finishes known as anti pilling finishes.

To prevent pilling close fabric construction is recommended. Tightly twisted yarns and longer staple fibres are helpful in preventing pilling. Fulling of wool, resin finishes on cotton are anti pilling finishes.

2.9 Loft and Resiliency:

Loft is the ability of a fibre to spring back to original thickness after being compressed. Resiliency is the ability of a fibre to bounce back to shape following compression, bending or similar deformation. Wool and silk fabrics are more resilient. They can be deformed, crushed or wrinkled during wear but they come to shape upon hanging. Elastic recovery is an important factor while evaluating the resilience of a fibre. Usually good elastic recovery indicates good resiliency.

2.10 Static Electricity:

This is the electricity produced by the friction of a fabric against itself or some other object. If a fabric is better conductor of electricity, it conducts away the electricity that is produced. But if the material is not a good conductor, the electricity produced cannot be conducted away, but it tends to pile up on the surface of the fabric. It the material comes in contact with a good conductor, a shock or transfer occurs. It may produce sparks, in gaseous atmosphere, it may give explosions. So it is a hazard in places where materials which are highly inflammable are present. So the use of synthetics is prohibited in operation theatres. Static electricity rapidly develops in cold and dry atmospheres. After wearing synthetics for few hours, it is better to wipe the garments with a wet towel. It carries away the electricity produced. Static electricity makes the fabric to cling to the body of the wearer. It attracts more dust and thus gives unsightly appearance. Fabrics cling to the machinery & thus cutting and stitching of garments is made difficult.

Antistatic finishes are given to fabrics in order to inhibit the piling up of static electricity on fabrics. But this is washed off after few washes.

2.11 Feltability:

It is the ability of fibre to mat together. Using this property, it is possible to produce fabrics without the complicated processing of spinning and weaving. These are termed as non – woven felted materials. Some rug materials, carpet materials and apparels are produced by felting. The ability of wool to coil together, interlock & shrink when subjected to heat, moisture and pressure is responsible for felting of wool fibres. In fact the other fibres are also felted by using a suitable adhesive.

REFERENCES

- Corbman B. P (1983) Textiles-fiber to fabric, Mc Graw-Hill lnt., USA

- Kadolph S J (2013) Textiles: Pearson New International Edition, Pearson Education Ltd, Asia

- Noemia, D Souza (1998) Fabric Care , New Age Publications

- Vatsala, R. 2003. Textbook of Textiles and Clothing. New Delhi. Indian Council of Agriculture Research

- Wynne A (1997) Textiles The Motivate Series, Macmillan

- http://bieap.gov.in/Pdf/CGTPaperII.pdf

- http://textilelearner.blogspot.com/2012/02/properties-of-fiber-properties-of.html

ASSIGNMENT

- Identify the different properties of the textile products

- List any five important secondary properties we need for clothes and why?

- Identify any five important properties that help in providing comfort to the wearer

THERMAL, CHEMICAL, BIOLOGICAL PROPERTIES AND MOLECULAR STRUCTURE OF TEXTILE FIBRES

- INTRODUCTION:

After the primary and secondary properties thermal behavior, the resistance to biological organism and resistance to chemicals and other environmental conditions are also important to study especially for providing hygienic clothes.

- THERMAL PROPERTIES:

The thermal behaviour of fibres is also an important factor for determining their performance and care. The burning characteristics of fibres help in fibre identification.

Among the textile fibres which are in use, some are heat sensitive and some are not heat sensitive. Heat sensitivity is the ability to soften, melt or shrink when subjected to heat like plastic. This category of fibres is also known as thermoplastic fibre. All synthetic & acetate are thermoplastic fibres. Others which are not heat sensitive are non-thermoplastic fibres. The heat sensitivity of a fibre may be due to the vibration of molecules in the fibre by heat. These fabrics need to be finished after washing, at safe, lower and recommended temperatures.

We feel comfortable when we wear some garments and we feel hot with some other garments this is mainly due to the heat conductivity of fabrics. Heat conductivity is the ability of fibres to conduct away heat from the body. This is also an important factor since; it contributes the use of certain fabrics in a particular season.

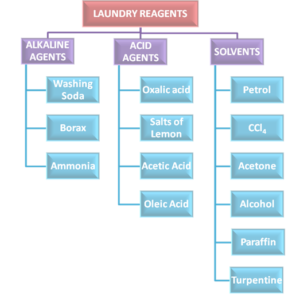

- CHEMICAL PROPERTIES:

The reaction of fibres to various chemicals is helpful in use and care of fabrics, chemical reactivity is the effect of acids, alkalies, oxidizing agents and solvents. The fibres react differently to various chemicals and these are explained under each fibre.

- BIOLOGICAL AND OTHER PROPERTIES:

Biological & other properties such as ageing resistance, sunlight resistance, resistance to moths, mildew and microorganisms play an important role in determining the performance of fabrics in use and care. All these are discussed in detail under each fibre.

- MOLECULAR STRUCTURE OF FIBRES:

As any other matter, textile fibres are also having chemical structure. The chemical structure of fibres is different from one another. For example: Cotton fibre is made up of cellulose which consists of hydrogen, carbon & oxygen. The way in which the chemical elements are arranged is what makes cotton different from polyester which has the same chemical constituents. The chemical structure affects fibre properties such as strength, elongation, resiliency, density, moisture content, sunlight and ageing resistance, dye absorption and electrical behaviour.

The fibre morphology refers to the molecular arrangement of fibre. The molecules in fibres are in the form of chains. These are known as polymers. Polymerization is the process of joining together small molecules known as monomers. The longer the chains, the higher the degree of polymerization.

The arrangement of molecules in these fibres can be described in terms of molecular orientation and amorphous regions. When the molecules of fibres are parallel to each other and also parallel to the longitudinal axis of the fibres, the arrangement is said to be highly oriented structure. If the molecules are arranged in haphazard way or at random, it is termed as amorphous or low oriented structure. A crystalline structure occurs when the fibre molecules are parallel to each other but not necessarily parallel to the fibre axis.

In a single fibre, it is common to find both amorphous & crystalline regions and fibres vary in the proportion of oriented, crystalline and amorphous regions.

The molecular arrangement of natural fibres is difficult to change except in cotton where the molecules tend to decrystallise by mercerization finish.

The man-made & synthetic fibres when extruded through the spinnerette consist of only random arrangement but when they are stretched they become thin and tend to take oriented structure. It improves the strength, elongation, moisture absorption, abrasion resistance & dyeability of fibres.

The properties like elasticity, strength etc are also dependent on the strength of the bonds between molecules. These molecular chains are held together by cross links or inter chain attractions or bonds such as Hydrogen bonds & Vander walls forces. Hydrogen bonds are stronger than vanderwalls forces even though both are found in crystalline arrangements. Hydrogen bonding occurs when the positive hydrogen atoms show attraction towards negative oxygen or carbon present in another chain. Thus the molecular structure of fibres is an important factor that affects the properties of fibres.

The molecules are held together in a chain like formation within a macromolecule by strong electronic force known as valency bonds. For example cellulose which is the base of cotton is formed by the polymerization of small, simple molecules into a larger complicated macromolecule.

REFERENCES

- Corbman B. P (1983) Textiles-fiber to fabric, Mc Graw-Hill lnt., USA

- Kadolph S J (2013) Textiles: Pearson New International Edition, Pearson Education Ltd, Asia

- Noemia, D Souza (1998) Fabric Care , New Age Publications

- Vatsala, R. 2003. Textbook of Textiles and Clothing. New Delhi. Indian Council of Agriculture Research

- Wynne A (1997) Textiles The Motivate Series, Macmillan

- http://bieap.gov.in/Pdf/CGTPaperII.pdf

- http://textilelearner.blogspot.com/2012/02/properties-of-fiber-properties-of.html

- http://textilelearner.blogspot.com/2011/07/termal-properties-of-textile-fibers.html

- http://textilestudy365.blogspot.com/2017/10/chemical-properties-of-textile-fibers.html

- https://study.com/academy/lesson/textile-fibers-definition-properties-types.html

ASSIGNMENT

- Identify the different properties of the textile products

- List any two important properties which are important in laundering clothes

- List the parts of textile fiber structures

- List the bonds present in textile fibers

COTTON FIBRE

- INTRODUCTION

Cotton is a seed hair obtained from the pod of the cotton plant that belongs to malvaceae family and class Gossypium. It is classified as a natural, cellulose, seed, staple fiber measuring 10-65mm in length and white to beige in color in their natural state. Cotton fiber grows from the surface of seeds in pods, or bolls, of a bushy mallow cotton plant hence it is called as seed hair. It is composed basically of a substance called cellulose, on burning cotton smells of burning paper and leaves a grey fluffy ash. As cotton occupies the 50% of consumption of fibers by weight in the world, it is called as the king of all fibers.

The origin of the fibre is unknown. Archaeologists confirm that cotton was grown in Egypt about 12000 BC. Evidences of growing cotton in India about 3000 BC are existing. Most of the earlier records also confirm that India was major country that grew cotton and exported to other countries. The varieties of cotton that were grown in Egypt were very fine compared to the rest of the world and considered as good quality. The term ‘Egyptian Cotton’ used even today indicates fine quality.

- CULTIVATION OF COTTON

Cotton is mostly grown in USA, India, and Egypt. Cotton. It requires 200 days of continues warm weather with adequate moisture and sunlight, frost is harmful to the plant. March and April months are suitable for plantation.

Cotton is cultivated in a warm humid climate. Black soil is considered best as it can hold moisture well. The cotton seeds are sown in fields around 3-4 feet apart in parallel rows. Irrigation is compulsory for plants growth. The plant grows to its full form within 80-1000 days and blossoms appear on plants. When open, it is creamy white in color which turns into pink within a day. The pods appear within 50-80 days and after attaining maturity, it bursts open and exposes the white fleece. Picking of cotton is done manually or by use of machine. Hand picking is very common in labour intensive countries and machines are employed in all western countries. The quality of cotton largely depends on picking operation. If the fleece alone is picked up carefully avoiding the burs and dried leaves, cotton will have good quality and is priced high. Of more impurities are present in cotton, it needs more cleaning, thus it is priced low.

- PROCESSING OF COTTON

After cotton is picked, it is taken to a ginning mill where the fibre is separated from its seed. Generally around 4,000 fibres emerge from a single cotton seed. Fine variety cotton can yield as much as 20,000 fibres from each seed. When cotton arrives at ginning mill, it contains seeds burs, leaf fragments, dirt etc. which should be removed before it is sent for spinning. Cotton gin, a machine invented by Whitney in 1974 is capable of separating cotton fleece from its impurities. It has rows of revolving saw toothed bands that pull the fibre away from the seeds and the impurities. Cotton seeds are important by-products from which oil is extracted. Cotton free from major impurities are baled and sent to spinning factories.

4. MANUFACTURING OF COTTON

4.1. Hand Made Cotton:

The tools and appliances used by the cotton weavers consist of spinning wheel (charka) spindle (takli) and a bow shaped beater (dhun). The threads then formed are wound on a bamboo reel and from which warp of the handloom is set to weave the fabric

4.2. Machine made Cotton:

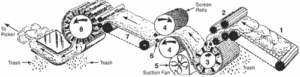

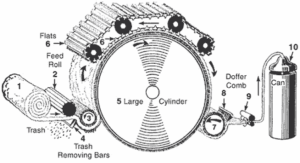

Manufacturing by machine involves the following steps;

- Preparation: The fibers are first removed from the seeds, leaf fragments, dirt and other materials. The seeds are removed by the cotton gin.

- Forming the laps: In this step dirt in the cotton is removed and fibers into a soft roll or lap. Then several laps are combined into one.

- Carding: The fibers are drawn together to form a loose rope or sliver.

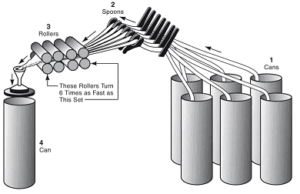

- Doubling: Slivers are combined.

- Combing: It is continuous and refinement of the carding process. These are free from woody stalk, used for finer quality fabrics.

- Drawing: Slivers are combined and smoothened, stretched that could cause too many variations if the slivers are feed singly. The slivers given first twist and wound on to bobbins.

- Roving: The bobbins are placed on the roving frame where further drawing and twisting takes place, until the cotton stock is about a pencil lead in diameter.

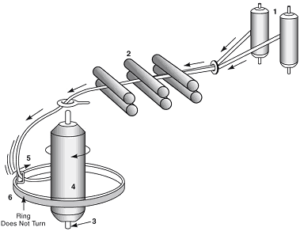

- Spinning: Done on the spinning frame where the stock passes through sets of high-speed rollers and gives the yarn of desired thickness.

- Weaving and dyeing: Any variety of weaves can be used for the cotton. Dyes are applied to raw cotton at fiber, yarn or fabric stage.

- Finishing: Both performance finishes and functional finishes are given to the cotton.

5.PROPERTIES OF COTTON FABRICS

5.1. PHYSICAL PROPERTIES

5.1.1. Structure

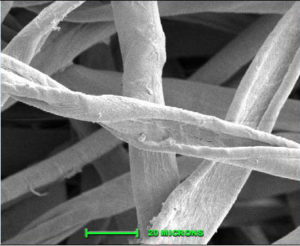

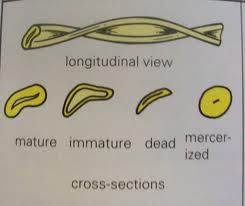

Cottonfibre is a cellulosic unicell that shows a base and tapering edges. It is a staple fibre ranging from ½ ” to 2 ½ ” in length. The diameter ranges from 12 to 20 micrometres. Cotton unicell shows outer cuticle (1), primary wall, secondary wall and a central canal called lumen (5). It is flat ribbon like with twist under microscope called ‘convulsions’. Matured fibres show narrow lumen and immature fibres show large lumen. The cross sectional shape of cotton fibre is similar to a kidney shape. Cotton fibre before ball opening exhibits round cylindrical shape but when exposed to outside atmosphere the cell sap dries up and makes it to flatten and loose its luster. About 65-70% of cotton fibre is crystalline and 35-30 % is amorphous.

5.1.2. Strength

The strength of cotton fibre is regarded as medium and the tenacity of cotton ranges from 3.0 to 5.0 grams per denier. One unique feature of cotton is its increase in strength when wet. When wet, it shows the strength equal to 110 to 120 % of its dry weight. The tenacity of cotton is increased when it is mercerized.

5.1.3. Elasticity

Cotton fibre has low elongation due to its crystalline structure. Around 3-7 % elongation is found. Around 75 % of elastic recovery is recorded at 2 % elongation. The elastic recovery reduces with increase in percent of elongation. At 5 % elongation, cotton recovers only 50%

5.1.4. Resiliency

The resiliency of cotton is low. Cotton fabrics wrinkle very easily and require ironing after washing. Appropriate finishing process improves wrinkle resistance of cotton.

5.1.5. Abrasion resistance

Cotton shows medium resistance to abrasion.

5.1.6. Moisture Regain:

Cotton is a hydrophilic fibre. The moisture regain of the fibre is 8.5 % under standard conditions. Cottons are highly comfortable as summer wear due to high absorbency and good heat conductivity.

5.1.7. Dimensional Stability:

Cotton fibres are stable and do not shrink or stretch as they are unicellular. Fabrics may show shrinkage due to tensions during fabric construction. However, it needs pre-treatment to control shrinkage in use.

5.1.8. Thermal Properties:

Cotton fabrics are good conductors of heat and thus regarded as cool fibre. Under dry conditions cotton can absorb the body sweat and keep the wearer comfortable. Light weight, open structured cotton fabrics are highly comfortable during humid weather. Cotton being cellulosic fibre does not melt but only scorches at high temperature of around 2500C as it withstands moderate temperatures, it can be ironed safely.

Cotton fibre burns slowly in flame and continues to burn after removal from flame as it supports combustion. It gives paper smell and leaves a small amount of fluffy ash as residue.

5.2. CHEMICAL PROPERTIES:

5.2.1. Effect of alkalies:

Cotton is highly resistant to alkalies. It can withstand all alkaline reagents and soaps. Alkalies such as sodium hydroxide and ammonia are used for finishing of cotton to impart desirable qualities.

5.2.2. Effect of acids:

Cotton’s resistance to acids is inferior to its resistance to alkalies. It shows good resistance to dilute organic acids such as acetic and citric acids. Prolonged exposure may tender cotton. Dilute or strong mineral acids such as sulphuric acids will destroy cotton

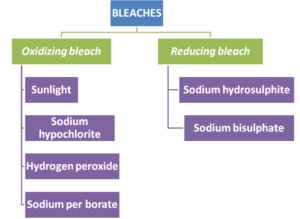

5.2.3. Effect of bleaches:

Cotton can withstand chlorine and perborate bleaches and not easily damaged unless it is very strong. Heavy bleaching may turn white cottons yellow reducing its strength.

5.2.4. Effect of Solvents:

Cotton is soluble in cuprammonium hydroxide and cupriethylenediamine. For rest of the solvents cotton exhibits resistance.

5.3. MISCELLANEOUS PROPERTIES:

5.3.1. Effect of Sunlight:

Prolonged exposure to sunlight disintegrates cotton by turning it to yellow. The presence of dyes and other finishing agents and pollutants may also augment the deterioration.

5.3.2. Effect of Mildew:

Cotton is affected by bacteria and fungi such as mildew. Cottons can be boiled safely to remove microorganisms. Storing away from moisture prevents from developing mildew black spots on fabric.

5.3.3. Effect of Moths:

Moths and beetles will not affect cotton but it is damaged by silver fish which eats cotton cellulose.

5.3.4. Effect of Perspiration:

Cotton is not affected by perspiration. However, the dyes used may not be fast.

6. FINISHES GIVEN TO COTTON:

Cotton, being in grey, may not be a fabric opted by everybody. There is large scope for finishing cotton to produce qualities in which cotton lacks.

- Preparatory finishes- Scouring, bleaching and singeing

- Routine finishes- Calendaring, tentering.

- Special purpose finishes-

- Sanforization – compressive shrinkage for maximum preshrinking.

- Mercerization – to improve strength, luster, absorbency and affinity for dyes.

- Wash n wear – for no ironing.

- Wrinkle resistance – free from wrinkles, for retention of appearance.

- Water repellency – for resistance to water and rain

- Stiffening- for building body and to provide smoothness

- Schrenerising – for producing luster on the surface of starched products

- Parchmentization- to impart transparency and permanent stiffness to cotton fabrics.

7. CONSUMER PREFERENCE:

Cotton is regarded as ‘king of fibres’ due to the following reasons:

- Cotton is a highly versatile It can be made into different fabrics starting from very light to heavy fabrics. Use of different methods of fabric construction has increased its versatile nature. Cotton fiber can be spun alone or it can be blended with other textile fibers such as linen, wool, silk, viscose rayon, polyester, and nylon. It serves the purpose of clothing or apparel, home furnishings and industrial fabrics by giving the comfort, durability, fashion and ease for care etc. The greatest amount of cotton is used for apparel purpose. As all cotton fabrics are used for comfort, and its appearance. Cotton blended with polyester is durable press fabric.

- It can be blended with polyester blended fabrics with specific features.

- It is highly comfortable for tropical climate of India. It provides coolness to the wearer by absorbing the sweat due to its hygroscopic nature. Its absorbency combined with good heat conductivity makes it highly suitable for summer wear.

- Generally cotton is durable and it can be made highly durable by carefully choosing the yarn twist and fabric construction and the finish. Knitted cottons form the best material for hosiery.

- Cotton’s ability to wash well is a boon to consumers. As cotton increases its strength when wet, it leaves the consumer with liberty to use friction for washing. It can withstand boiling during sterilization to make it suitable for hospital wear.

- Cotton fabric is considered as ‘ever green fabric’ by fashion goers. It can be styled to suit all fashion designs and thus it is on hot fashion.

- Industrial uses of cotton include abrasives, book bindings, luggage and handbags, shoes and slippers, tobacco cloth, woven wiping clothes, and wall covering fabrics.

Cotton Mark

REFERENCES

- Corbman B. P (1983) Textiles-fiber to fabric, Mc Graw-Hill lnt., USA

- Dantyagi, S. 1959. Fundamentals of textiles and their Care. New Delhi. Orient Longman Limited.

- Deulkar, D. and Tarabai.1967. Household textiles and laundry Work. 3rd ed. Delhi.Atma Ram and Sons Ltd

- Kadolph S J (2013) Textiles: Pearson New International Edition, Pearson Education Ltd, Asia

- Noemia, D Souza (1998) Fabric Care , New Age Publications

- Vatsala, R. 2003. Textbook of Textiles and Clothing. New Delhi. Indian Council of Agriculture Research

- Wynne A (1997) Textiles The Motivate Series, Macmillan

- https://www.textileschool.com/129/cotton-fibers-the-king-of-fibers/

- https://journals.sagepub.com/doi/abs/10.1177/004051754801800201?journalCode=trjc

- https://www.textilemates.com/cotton-history-production-processing/

ASSIGNMENTS

- Identify textile products made of cotton fibers

- What are the finishes given to cotton textiles?

- Why cotton is called as ‘King of Fibers’?

- What types of clothes generally made of cotton that provide comfort to the wearer? List them

LINEN FIBER

1. INTRODUCTION:

Flax is a bast fibre, obtained from the plant, Linum usitatissimum. It is one of the oldest fibre known to mankind as early as 10000 to 8000 BC.

Flax is basically made of cellulose substance. Linen yarn is made from fibers removed from the stem of the slender flax. These fibers held together under the stem bark principally by a gummy substance (pectin).

2. HISTORY: Flax is one of the oldest textile fibers. Fragments of linen fabric have been found in pre historic lake dwellings in Switzerland, linen mummy wraps more than 3000 years old have been found in Egyptian tombs. There is evidence that flax was used as textile in 6000 & 4000 B.C. in the Middle East and Egypt. Until 18th century, flax was the major textile fibre, which was replaced with cotton, in the 19th and 20th century. Today flax is a prestige fiber as a result of its limited production and relatively high cost.

The unique and desirable characteristic of flax are its body, strength, durability, low pilling, and linting tendencies, pleasant hand, thick and thin texture.

Most flax is produced in Western Europe, in Belgium, France, Italy, Ireland, the United Kingdom, Germany, heathlands, Switzerland. Flax is also produced in Russia, Belarus and New Zealand

3. STRUCTURE: The primary fiber of flax averages 5.0 to 21.5 inches in length and 12 to 16 micro meters in diameter. Flax fibers can be identified microscopically by crosswise markings called nodes or joints that contribute to its flexibility. The nodes may appear to be slightly swollen and resemble the joints in a stalk of corn or bamboo. In cross section, the fibre appears polygonal.

3. STRUCTURE: The primary fiber of flax averages 5.0 to 21.5 inches in length and 12 to 16 micro meters in diameter. Flax fibers can be identified microscopically by crosswise markings called nodes or joints that contribute to its flexibility. The nodes may appear to be slightly swollen and resemble the joints in a stalk of corn or bamboo. In cross section, the fibre appears polygonal.

Flax fibers are slightly greyish when due retted and more yellow when water retted. Short flax fibers are called tow, the long, combed; better quality fibers are called line. The line fibers are readied for wet spinning into yarn. The tow fibers must be carded before dry spinning into yarns for heavier fabrics for furnishings.

Flax fibre has a longer polymer and high degree of polymerization and greater orientation and crystalline area.

4. CHEMICAL COMPOSITION OF FLAX

|

Component |

% |

Contributing Property |

|

| Cellulose | 85-87% | ||

| Lignin | 2.5-4 % | Makes the cellulose rigid, is seen in amorphous areas; its presence has an impact on tenacity and resilience | If not removed properly it affects the hand and flexibility of the fibre |

| Pectin and Hemicelluloses |

19 % | Binds the fibre into bundles, determines lustre and hand of the fibre | If not removed properly it affects the fineness and spinning ability of the fibre |

5. MANUFACTURING PROCESSES

Fibre extraction of flax is similar to jute. During harvesting, the flax is pulled, not cut. Both biological and chemical retting can be done to the stalks. Biological retting produces better quality of fibres and is more economical. Cottonization of flax is a chemical retting. The steps in fibre extraction are as follows:

5.1 RETTING: Dew retting or water retting is done. Enzymes may also be used for retting, which act on the pectin.

5.2 BREAKING: The stalk becomes partially separated from the fiber when the wet plants are placed in the fields to dry. When the decomposed woody tissue is dried it is crushed by being passed through fluted iron rollers. This breaking operation reduces the stalk to small pieces of bark called shives.

5.3 SCUTCHING: It separates the bast from the woody core. The scutching machine removes the broken shives by means of rotating wooden paddles, thus finally releasing the flax fiber from stalk. This operation can be done by hand by beating the stalks with a blunt flat wooden or metal beater.

5.4 HACKLING (COMBING): This process prepares the fibres for spinning. The simple combing process known as hackling. It straightens the flax fibers separates the short from the long staple, and leaves the longer fibers in the parallel formation. For very fine linen, a hackling is done by hand. A faster and more efficient combing, hackling is done by machine.

This process produces

- Long fibre bundles called line

- Short tangled fibre called tow

5.5 SPINNING: The short staple flax fibers, called tow, are used for the spinning of irregular linen yarns. Tow is put through a carding operation, similar to the carding of cotton staple, which straightens the fibers and forms them into a silver ready for spinning into yarn. The long staple fibers are used for fine linens. These are called line, sometimes dressed flax. Line fibers are from 12 to 20 inches in length. They are put through machines, called spreaders, which combine fibers of same length, laying them parallel so that the ends overlap. The silver thus formed passes through sets of rollers making a rove for the final spinning process which inserts the final twist. Although flax is one of the strongest fibers, it is inelastic and requires a carefully controlled, warm, moist atmosphere for both methods of spinning.

5.6 DRY SPINNING: Dry spinning does not use moisture. It produces rough, uneven yarns, which are not especially strong. These yarns are used for making coarse, heavy and inexpensive linen fabrics.

5.7 WET SPINNING: This method requires a temperature of 120 Degree Fahrenheit, which is conductive to the production of soft ,even yarns .By passing the roving through hot water, the gummy substance on the fiber is dissolved, permitting drawing out the roving into the fine yarn of high yarn count.

6. PROPERTIES OF FLAX

6.1 Strength: Flax shows increased strength in wet condition, like cotton.

6.2 Tenacity: 4.8 to 6 g/denier

6.3 Specific gravity: 1.54

6.5 Elongation: low

6.6 Elastic recovery: 65% recovery at 2% elongation. Flax is a stiff fibre.

6.7 Drapability: Linen has more body than cotton and drapes better.

6.8 Heat conductivity: Linen has most suitable for summer apparel, as it allows the heat of the body to escape.

6.9 Moisture regain: 12% more absorbent than cotton

6.10 Absorbency: It absorbs moisture and dries more quickly. It is therefore excellent for handkerchiefs and towels.

6.11 Cleanliness and wash ability: Linen launders well and gives up stains readily, its softness is enhanced by repeated washing.

6.12 Reaction to bleaches: Linen does not stain readily as cotton, but it is also more difficult to bleach. Like cotton, it is weekend by sodium hypochlorite bleaches, sodium perborate bleaches are effective and safer.

6.13 Shrinkage: Linen does not shrink but preshrink age finishing is desirable.

6.14 Effect of heat: Linen scorches and flames in a manner similar to cotton.

6.16 Effect of light: Linen is more resistant to light than cotton, but it will gradually deteriorate from protracted exposure.

6.17 Resistance to mildew: Like cotton, linen is vulnerable to mildew.

6.18 Resistance to insects: Like cotton, linen is not damaged by moths. Damage by other insects is uncommon.

6.19 Reaction to alkalies: Linen like cotton is highly resistant to alkalies. Linen may also be mercerized.

6.20 Reaction to acids: Linen is damaged by hot dilute acids and cold concentrated acids but not by cold dilute acids.

6.21 Affinity for dyes: linen does have good affinity for dyes. However, it is possible to obtain dyed linen that has good colorfastness.

6.22 Resistance to perspiration: Acid perspiration will deteriorate linen. Alkali perspiration will not cause deterioration. But discoloration may occur.

6.23 Resistance to sunlight: More sunlight resistant than cotton

7. FINISHING PROCESSES: Linen is commonly treated by bleaching.

7.1 BLEACHING: Two methods are used grass bleaching and chemical bleaching. Grass bleaching the finest results. Although chemical bleaching is chiefly used , it may adversely effect the durability of the finished fabric owning to the weakening effects of the chemicals.

7.2 BEETLING: For flexibility and thickness.

7.3 CALENDERING: For luster and smoothness.

7.4 MERCERIZING: For luster

7.5 SIZING: for added body

7.6 WRINKLE RESISTANCE: For resilience and easier care.

8. USES OF LINEN

Short coarse fibres are used in making pulp for paper, cigarette paper, packaging, laminates, coatings, particle boards, non wovens for geo textiles and chemo textiles.

9. MEASURE

The standard measure of flax yarn is cut .If one pound of flax is drawn out to make 300 yards, the yarn is known as Ne 1. When drawn out to make twice 300 yards, it is labelled Ne 2 .The higher the yarn count, the finer the yarn.

10. CARE OF LINEN: Linen fabrics can be dry cleaned, machine washed or bleached with chlorine bleaches. As linen fabrics have low resiliency, they tend to crease more and require pressing. Linen is resistant to alkalis, organic solvents and high temperature.

11. CONSUMER PREFERENCE: Linen has long been used for a wide variety of apparel and home furnishings. In fact, the oft used term of linens which refers to such home furnishings as sheet, pillowcases, towels, table cloths. Linen is now used to a limited extent. Linen apparel includes items for warm weather use, high fashion, casual and professional wear. Industrial products include luggage, bags, purses and sewing threads. Linen fabrics are used in upholstery and window treatment, because of their durability, interesting and soil hiding textures and versatility in fabrication and design.

REFERENCES

- Textiles, 10th addition, Sara J. Kadolph, Published by, Dorling Kindersley India Pvt. Ltd.

- Textiles – Fiber to Fabric, 6th addition, Bernard P. Corbman.

- Handbook of Natural Fibres: Types, Properties and Factors Affecting Breeding and cultivation. Vol. I, Edited by Ryszard M Kozłowski, Woodhead Publishing, 2012

ASSIGNMENT

- List the products made of Linen

- List the reasons why linen is more absorbent that cotton

- Collect the pictures regarding the linen products

JUTE FIBRE

1. INTRODUCTION

Jute is extracted from the bark of the white jute plant, Corchorus capsularis and to a lesser extent from tossa jute (C. olitorius). It flourishes in tropical lowland areas with humidity of 60% to 90%. A hectare of jute plants consumes about 15 tonnes of carbon dioxide and releases 11 tonnes of oxygen. Yields are about 2 tonnes of dry jute fibre per hectare.

Jute is a natural fiber popularly known as the golden fiber. It is one of the cheapest and the strongest of all natural fibers and considered as fiber of the future. Jute is second only to cotton in world’s production of textile fibers. India, Bangladesh, China and Thailand are the leading producers of Jute. It is also produced in southwest Asia and Brazil. The jute fiber is also known as Pat, kosta, Nalita, Bimli or Mesta (kenaf).

Kenaf known as Mesta or Ambari (species Hibiscus Cannabinus) is also considered as a variety of Jute. It is cultivated in Indian subcontinent, Thailand, China and Africa. The two main types of jute, white jute (Corchorus Capsularies)and dark jute or tossa (Corchorus Olitorius) are grown in India, Bangladesh, Thailand, China, south Asian countries and Brazil.

India is the largest producer of jute goods in the world, while Bangladesh is the largest cultivator of raw jute. The cultivation of Jute in India is mainly confined to the eastern region states – West Bengal, Bihar, Assam, Tripura, Meghalaya, Orrissa and Uttar Pradesh. Nearly 50 percent of total raw jute production in India alone figures in West Bengal.

2. CULTIVATION OF JUTE

Jute requires a warm and humid climate with temperature between 24° C to 37° C. Constant rain or water-logging is harmful. The best soil for jute is the gray alluvial soil of good depth, receiving salt from annual floods. Jute is harvested between 120 days to 150 days from sowing when the flowers have shed. Early harvesting gives good healthy fibers. The harvested plants are left in field for 3 days for the leaves to shed. The stems are then made up into bundles for steeping in water. Steeping is carried out immediately after harvest.

3. PROCESSING OF JUTE

3.1 Retting: Retting is the process of extracting fiber from stem of the plants. The various ways of Retting are:

3.1 Retting: Retting is the process of extracting fiber from stem of the plants. The various ways of Retting are:

Mechanical retting (hammering), chemical retting (boiling & applying chemicals), steam/vapor/dew retting, and water or microbial retting. Among them, the water or microbial retting is a century old but the most popular process in extracting fine fibers. However, selection of these retting processes depends on the availability of water and the cost of retting process.

To extract fibers from jute plant, a small stalk is harvested for pre-retting. Usually, this small stalk is brought before 2 weeks of harvesting time. If the fiber can easily be removed from the Jute core, then the crop is ready for harvesting.

After harvesting, the jute stalks are tied into bundles and submerged in running water. The stalk stays submerged in water for around 20 days. However, the retting process may require less time if the quality of the jute is better. In most cases, the fiber extraction process of fibers in water retting is done by the farmers standing under water.

When the jute stalk is well retted, the stalk is grabbed in bundles and hit with a long wooden hammer to make the fiber loose from the jute. After losing the fiber, the fiber is washed with water and squeezed till the last drop of water. The extracted fibers is further washed with fresh water and allowed to dry on bamboo poles. Finally, they are tied into small bundles to be sold into the primary market.

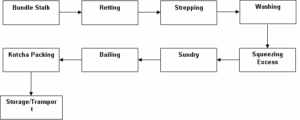

4. EXTRACTION OF FIBRE:

The jute plant’s fibers lie beneath the bark and surround the woody central part of the stem. To extract the fibers from the stem, the process is carried out in the following stages:

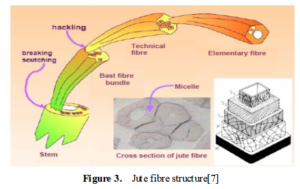

5. JUTE FIBRE MORPHOLOGY

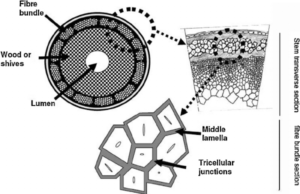

Jute is an agricultural product and chemically known as ligno-cellulosic fiber. The fibres are arranged in the bast or phloem region of the jute plant consisting of pyramidal wedges, fibre bundles in each wedge are further arranged in large number (8 to 12) layers. The ultimate cells of individual fibres are formed by the alpha-cellulose where as the presence of hemi-cellulose and lignin cements the ultimate fibres. As a result jute fibres form a mesh or network in which the individual fibres or strands have no identity.

6. FIBRE COMPOSITION:

Jute is mainly composed of polysaccharides and lignin but it also contains smaller amount of fats and waxes, pectin, nitrogenous, coloring and inorganic matters. The polysaccharides or glucose units are of two types such as alpha-cellulose (C6H10O6)n and hemi-cellulose.

|

Chemical composition of jute fibre |

|

|

Constituents |

% |

| Cellulose | 60 – 62 |

| Hemi Cellulose | 22 – 24 |

| Lignin | 12 – 14 |

| Others | 1 – 2 |

7. STRUCTURE OF JUTE:

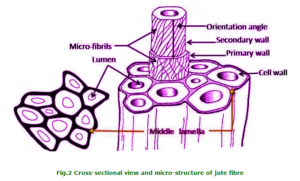

7. STRUCTURE OF JUTE:

Jute is multicelled in structure (Fig. 3). The cell wall of a fibre is made up of a number of layers: the primary wall and the secondary wall (S), which again is made up of the three layers (S1, S2 and S3). As in all lignocellulosic fibres, these layers mainly contain cellulose, hemicellulose and lignin in varying amounts. The individual fibres are bonded together by a lignin-rich region known as the middle lamella. Cellulose attains highest concentration in the S2 layer (about 50%) and lignin is most concentrated in the middle lamella (about 90%) which, in principle, is free of cellulose. The S2 layer is usually by far the thickest layer and dominates the properties of the fibres. Cellulose, a primary component of the fibre, is a linear condensation polymer consisting of Danhydro- glucopyranose units joined together by ß-1, 4-glucosidic bonds. The long chains of cellulose are linked together in bundles called micro-fibrils (Fig. 3).

Jute is long, soft and shiny, with a length of 1 to 4 m and a diameter of from 17 to 20 microns. It is one of nature’s strongest vegetable fibres and ranks second only to cotton in terms of production quantity. Jute has high insulating and anti-static properties, moderate moisture regain and low thermal conductivity.

8. PROPERTIES OF JUTE FIBRE

| Property |

Jute |

Cotton |

| Ultimate cell length, L (mm) |

0.8 to 6.0 |

15 to 35 |

| Ultimate cell breadth, B (mm) |

10 to 25μm |

4 to 6μm |

| Length / Breadth (L/B) Ratio |

110 |

25,000 |

| Fineness (Denier) |

15 to 35 |

1.5 to 3.0 |

| Tenacity (gm/denier) |

3 to 5 |

2.5 to 4 |

| Elongation at break (%) |

1.0 to 1.8 |

6.5 to 8 |

| Density (gm/cc) |

1.46 |

1.56 |

| Degree of crystallinity (X-ray) |

55 to 60 % |

— |

| Angle of orientation (X-ray) |

7 to 90 |

— |

| Initial modulus |

17 to 30 N/tex |

|

| Flexural rigidity (dynes.cm) |

3.0 to 5.0 |

0.3 to 1.0 |

| Moisture Regain (%) at 65% R.H. |

12.5 |

8.5 |

| Moisture Regain (%) at 100% R.H. |

36 |

24 |

| Diameter swelling (%) at 100 % RH |

20 to 22 |

20 to 22 |

9. PHYSICAL PROPERTIES

9.1 Strength: Jute is a strong but low extensible fibre mainly due to composite like structure with highly oriented long chain molecules. Tossa jute is stronger than white jute.

9.2 Elasticity: Low

9.3 Resiliency: Low

9.4 Abrasion resistance: Very low

9.5 Moisture absorbency: Due to presence of numerous polar –OH groups, jute fiber shows good moisture absorption capacity.

9.6 Moisture Regain: Moisture regain value may be upto 36% at 100% relative humidity which is much higher than cotton. Since long chain molecules are almost aligned along the fibre axis, the swelling of jute fiber is found to be much more laterally than longitudinally. The diameter wise and cross sectional wise swelling of jute in water is about 20% and 44% respectively which are higher than cotton but the longitudinal swelling is only 0.4%. Water holding capacity of jute is about 500%.

10. THERMAL PROPERTIES: On heating to high temperature, jute fibre chars and burns without melting like cotton. Ignition temperature of jute is about 1930C.The high specific heat value (1360 J/kg/K) results good thermal insulation of jute.

11. CHEMICAL PROPERTIES:

11.1. Effect of alkalies: Jute fibres have poor resistance to alkali due to presence of hemicelluloses. Alkali treatment extracts out the hemicelluloses from the fibre structure making it weak. Treatment with 18 % caustic soda jute becomes slightly weaker but highly soft and crimpy due to irregular swelling. The process is popularly known as woollenisation.

11.2. Effect of acids: Jute fibres are weakened and destroyed by acids. The cellulose chains disintegrate due to hydrolysis in presence of acids. The mineral or inorganic acids are more effective than organic acids.

11.3. Effect of bleaches: The bleaching agents remove the natural colour from jute to make it white but at the same time partly remove the lignin and make the jute weaker and finer.

12. USES OF JUTE:

Jute is the second most important vegetable fiber after cotton not only for cultivation, but also for various uses. Jute is used to make sacks and coarse clothes and also being used for wrapping bales of raw cotton. Jute yarns are woven into fine fabrics to use as curtains, chair coverings, cheap quality rugs, hessian clothes, backing of linoleum and carpets. Jute was mainly used for making sacks but now things have changed and many other ways of utilizing jute has come up.

Jute began to lose its popularity with the advent of synthetic materials as the latter was more economical. But slowly people began to realize the negative impact of synthetic materials on the environment. Jute scores over synthetic materials largely due to its bio-degradable nature. Examples of such uses include containers for saplings, which can be planted directly with the container without disturbing the roots, and land restoration where jute cloth prevents soil erosion.

The fibers are used to make ropes. Jute rope has long been popular in Japan for use in bondage. Jute butts, the coarse ends of the plants, are used to make cheap clothes. It also helps in addressing the problem of deforestation as it also makes. Jute has a long history of use in the sackings, carpets, wrapping fabrics (cotton bale), and construction fabric manufacturing industry.

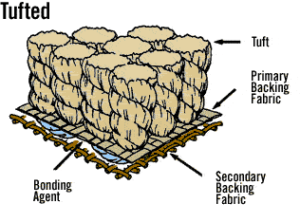

Jute can be used to create a number of fabrics such as Hessian cloth, sacking, scrim, carpet backing cloth (CBC), and canvas. Hessian, lighter than sacking, is used for bags, wrappers, wall-coverings, upholstery, and home furnishings. Sacking, a fabric made of heavy jute fibers, has its use in the name. CBC made of jute comes in two types. Primary CBC provides a tufting surface, while secondary CBC is bonded onto the primary backing for an overlay.

Diversified jute products are becoming more and more important to the consumer today. Among these are gift articles, handicrafts, wall hangings, shopping & carry bags, floor coverings, home textiles, high performance technical textiles, Geotextiles, composites etc.

13. FEATURES OF JUTE:

- Jute fiber is 100% bio-degradable and recyclable and thus environmentally friendly.

- It takes very short time to grow (4-6 months) which can be useful in growing other food crops.

- It is a natural fiber with golden and silky shine and hence called The Golden Fiber.

- It is the cheapest vegetable fiber procured from the bast or skin of the plant’s stem.

- It is the second most important vegetable fiber after cotton, in terms of usage, global consumption, production, and availability.

- It has high tensile strength, low extensibility, and ensures better breathability of fabrics. Therefore, jute is very suitable in agricultural commodity bulk packaging.

- It helps to make best quality industrial yarn, fabric, net, and sacks. It is one of the most versatile natural fibers that have been used in raw materials for packaging, textiles and non-textile construction, and agricultural sectors. Bulking of yarn results in a reduced breaking tenacity and an increased breaking extensibility when blended as a ternary blend.

- The best source of jute in the world is the Bengal Delta Plain in the Ganges Delta, most of which is occupied by Bangladesh.

- Advantages of jute include good insulating and antistatic properties, as well as having low thermal conductivity and moderate moisture regain. Other advantages of jute include acoustic insulating properties and manufacture with no skin irritations.

- Jute has the ability to be blended with other fibers, both synthetic and natural, and accepts cellulosic dye classes such as natural, basic, vat, sulfur, reactive, and pigment dyes. The resulting jute/cotton yarns will produce fabrics with a reduced cost of wet processing treatments.

- Jute can also be blended with wool. By treating jute with caustic soda, crimp, softness, pliability, and appearance of it are improved, aiding in its ability to be spun with wool. Liquid ammonia has a similar effect on jute, as well as the added characteristic of improving flame resistance when treated with flame proofing agents.

REFERENCES

- Corbman B. P (1983) Textiles-fiber to fabric, Mc Graw-Hill lnt., USA

- Kadolph S J (2013) Textiles: Pearson New International Edition, Pearson Education Ltd, Asia

- Vatsala, R. 2003. Textbook of Textiles and Clothing. New Delhi. Indian Council of Agriculture Research

- http://www.jute.com/green-jute/agriculture-raw-jute

- http://www.worldjute.com/about_jute/abj_intro.html

ASSIGNMENT:

- Collect any three products/ jute fibers from different products used at home

- Collect pictures of apparel products made of jute fibers or its blends

- List the uses of jute in various products around you

RAMIE FIBER

1. INTRODUCTION

Ramie belongs to the genus Boehmeria, commonly known as china grass, white ramie, green ramie and rhea. It is perennial plant, a member of the order Urticaceae or nettle which can be harvested six times a year. It is one of the oldest vegetable fibers and has been used for thousands of years. It produces a large number of un branched stems from underground rhizomes and has a crop life from 6 to 20 years. Chemical treatment is given to fibers for the removal of gums and pectins found in the bark.

Same process is used to transform ramie fibers into fabric as used for manufacturing linen from flax. The true ramie or China Grass or white ramie is cultivated in China. It has large heart shaped, broad leaves covered with white hair responsible for silvery appearance. Green ramie or rhea has smaller leaves than white ramie and is better suited to tropical climates, cultivated in peninsula. Normally ramie plant grows 1-2.5 m high. The fibers are located in the cortex layer of the stem underneath the thin bark. Leading producers of ramie are China, Taiwan, Korea, the Philippines and Brazil.

Ramie in China is usually harvested by hand as the canes mature. Uneven strands of ramie, makes harvesting a difficult task. Pounding and scraping are necessary processes to separate the fibres. After separation of fibers from woody matter and soft tissues, fibres remain in ribbon-like strips as they are held together by gums and pectin. The fibres are degummed by boiling or acid. Degumming weakens the fibre. Machines are not yet capable of performing all the steps necessary which is why ramie is not widely used.

It is often blended with cotton to make woven and knit fabrics. It is used in clothing, tablecloths, napkins and handkerchiefs. Apart from textile industry, ramie is used in fish nets, canvas, upholstery fabrics, straw hats and fire hoses.

2. PROCESSING OF RAMIE

Ramie’s fibers are present in the bark of the stalk. The stems are soaked in water for a few hours. The inner fiber is stripped away from the skin using a blunt knife. After drying the fibre in the shade, it is then split into narrow strips.

2.1 Stripping: Stripping is a process in which removal of all the phloem and some outer bark is carried out. The resulting strips are often referred to as China grass. Hand stripping is generally carried out on fresh stems and is said to yield better quality fiber than that produced by decorticating dry stems.

2.2 Ribboning: Process involving removal of the outer bark/epidermis and the bast from the woody core of the stem is referred as ribboning. Ribbons contain more of the outer parts of the stem than strips. The stems are usually fed between longitudinally fluted rollers for the removal of ribbons which crush the woody core and knock any wood fragments out of the bast. However, ribbons may also be obtained by another process using a modified decorticator in which the core is removed from the stem by the action of a moving drum.

2.3 Decortication: Mechanical decortication is most effectively carried out on either fresh green stems or dry stems. Dry decortication is a quicker process and has the advantage of not being restricted to the harvesting season. However, decortication of fresh stems is said to produce a better quality fiber. Mechanical decorticators built on the principle of subjecting the stem to a succession of blows to break up the woody core. The principle of successive slow blows treats the fibers more mildly and is congenial for the mechanical properties of the fiber. High velocity blades disintegrate stems which are fed into the drum resulting in fiber separation. The blades subsequently scrape away the epidermal, woody tissues from the fiber.

2.4 Washing and drying: The water soluble gums need to be removed after decortications and is done by washing. This also decreases transport costs to the degumming site. The extracted fibrous material, after washing, should be immediately dried or degummed to prevent the development of mildew. Degumming of fresh ribbons prevents loss in fiber value caused by mildew which develops in slowly or incompletely dried fiber.

3. CHEMICAL COMPOSITION OF RAMIE

| Table 2: Chemical composition of ramie fibre | ||||||||||

|

4. PROPERTIES

4.1. PHYSICAL PROPERTIES